Your basket is currently empty!

Crafting cheddar without costing the earth

We’ve made a few changes since 1833 but our commitment to the environment is stronger than ever. After all, only by taking care of our land, animals and surroundings will we be rewarded with the best cheddar, now and in the future.

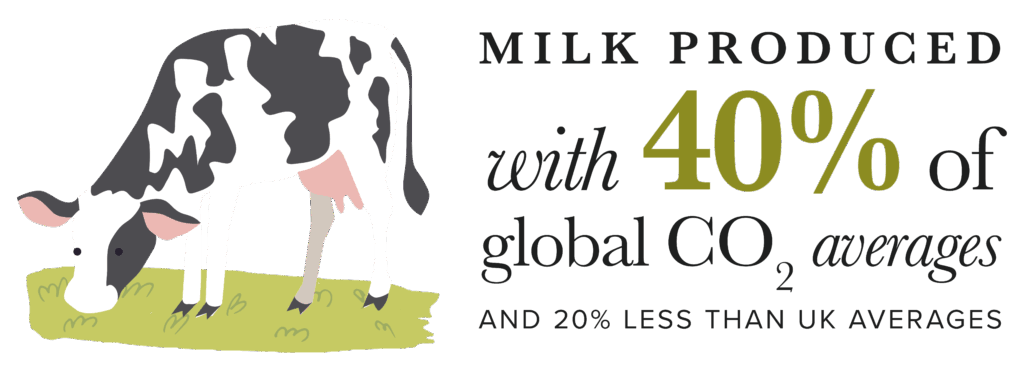

0.906kg CO2e/litre

Barber’s milk emissions (Global average >1.2kg)

222 days

spent outside

1.5k miles

of hedgerows

Our Nature Positive initiative is a collaborative effort that brings together our regenerative farming practices, commitment to biodiversity and habitat protection and creation, as well as a focus on responsible energy use and emissions reduction.

At Barber’s we let nature be natural.

Increasing biodiversity benefits our farms with increased pollinator numbers, a reduced need for chemicals and improved quality of soil. See our gallery below for some examples.

For us ‘Regenerative Farming’ is simply how we farm and have done since the beginning. It is a softer approach working with nature that prioritises soil health, biodiversity and ecosystem resilience. Here’s some of what we do:

Without soil, carbon would return to the atmosphere as Carbon Dioxide, the main greenhouse gas. By letting our nature be natural we are optimising our carbon capture. Having and planting herbal leys, cover crops and wildflower areas improve our carbon intake, quality of crops and food for our cows.

Through Nature Positive our teams and farmers work hard to understand our farming emissions.

All farms are assessed for their carbon footprint and their custodianship of the countryside. As of 2025 the Carbon Footprint per litre of milk is 40% of recognised global averages and 20% better than the UK averages.

All of our milk is sourced within a 32 mile radius of both dairies, supplied by farming families we know and trust. We have 8 Barber’s home dairy farms in addition to 146 dedicated dairy herds, farming 29,000 cows.

We prioritise our cows health and wellbeing, believing it’s critical that cows are provided free-range conditions throughout the year, where they can express their natural behaviours.

Happy and well-cared for cows produce better milk, and tastier cheese.

Rooted in regenerative principles all byproducts serve a purpose within our cheese production:

Water used and produced in the dairy gets filtered multiple times, purifying it, ready to be reused throughout the dairy.

Salted whey is used in our salted butter and unsalted whey is dried to become whey protein concentrate.

Excess Lactose is sold on to become plant bio food, as plants respond well to high sugar content or it can even be used in the brewing process of certain styles of beer.

The high-grade machines we use in our packing lines are able to measure and slice to get the most out of a 20kg block. The smaller slices that we cannot pack are sold to food manufacturers as cheese ‘scraps’. Still perfectly good cheese but are below the weight we need

Our cheese is matured in wooden boxes that get reused over and over again until they become unsuitable. We found that maturing the cheese in wooden boxes not only gives them a strong rectangular shape but they also cool down at a better rate providing better flavour.